In the summer of 2019, I noticed a vibration in my steering wheel while taking hard left turns. Although this was concerning, it was not a major issue until it noticeably affected the steering of the car while driving one morning. By the time I had reached my destination, the car was barely able to turn. After a quick inspection, it became clear that the right-side motor mount had collapsed and was resting on the steering rack. It also became clear that this had happened before and was poorly repaired with a MIG welder. The motor mount was an integral part of the front subframe, which supported the engine and the front suspension. Considering this was a lengthy repair, the car was put on a tow truck and parked for several months.

While the car was parked, I did some research on online forums and found that this was not an uncommon issue. Although it typically only occurs in racing or high-torque applications, the motor mounts on the front subframe are a weak point which tend to fatigue over time. Luckily, several companies have developed reinforcing plates which may be welded in to prevent these failures. These reinforcements were ordered, and a new subframe was acquired locally from a 1986 BMW 325i.

The process started by preparing all of the parts for welding. The reinforcing plates were cleaned up with a wire brush to remove the scale. The new subframe was cleaned using soapy water to remove the dirt/gunk; then, a wire brush was used to remove the paint, particularly near the welding points. In addition to this, reinforcing plates for the front anti-roll bar were designed in SolidWorks and cut out on a waterjet; although the anti-roll bar mounts were not damaged, they are another weak point, so reinforcing plates allow the option to upgrade the anti-roll bar in the future.

Once all of the parts were prepared, a friend of mine helped me TIG weld the reinforcing plates onto the subframe. The motor mount reinforcements were welded along the main crossmember, hammered down to form it against the curved motor mount profile, and then welded to create a closed section. With everything welded together, the oxidation was removed with a wire brush, and the subframe was painted with black chassis paint and clear coat.

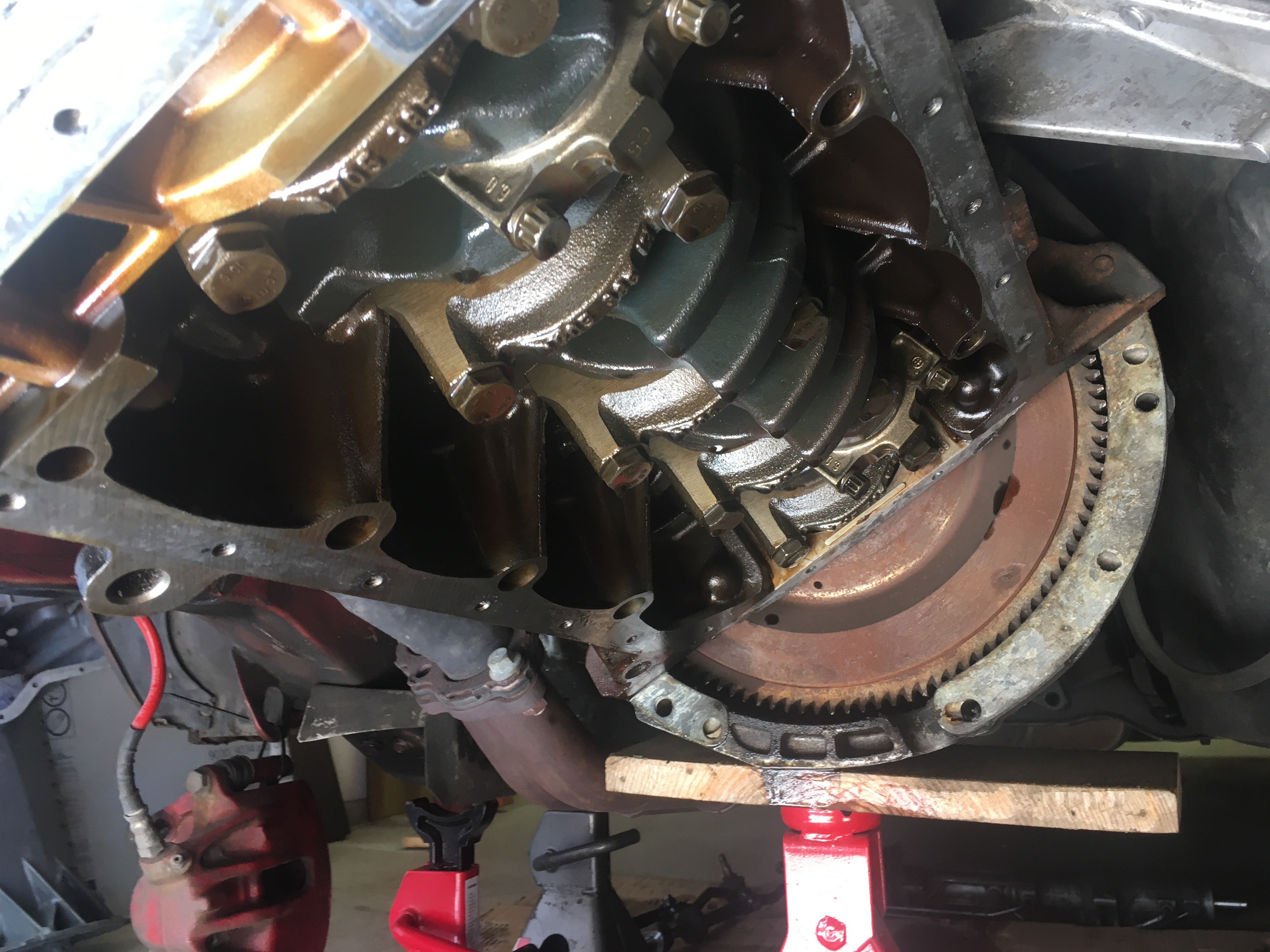

With the new subframe prepared, the car was parked in the garage, and the engine was suspended using an overhead support. The front end was lifted, and a floor jack was placed under the engine as a redundant support for safety. The motor mounts and outboard suspension members were disconnected, and the subframe / front suspension were lowered from the car.

The subframe is the main obstruction preventing the upper oil pan from being removed. This made it a perfect opportunity to drop and clean the upper oil pan, then replace the gasket between the pan and the engine block. The oil and gunk was removed using soapy water and oven cleaner. Old gasket material was scraped off, and the gasket was replaced.

The old subframe was stripped of its components, which were cleaned, painted, and swapped to the new subframe. Several components, including the control arms, were seized to the old subframe and required replacement. To prevent this from happening in the future, a liberal amount of marine grease was applied to the mating surfaces. In addition to these new components, the control arm bushings were replaced with 95A polyurethane units to provide improved road feel over the stock rubber units. A silicon-based lubricant was applied to these bushings to allow rotation without degrading the polyurethane.

After all of the suspension components and motor mounts were attached the new subframe, it was placed on a floor jack and slowly raised into position. The mounting holes were carefully lined up with the frame, and the engine was gently rocked back and forth to align with the motor mounts. Once everything was properly aligned, the assembly was raised and bolted to the frame. The suspension members were re-mated and torqued to spec. Once everything was reassembled, the vehicle was dropped, taken for a test drive, then brought in for a wheel alignement.